Looking for something else? Drop your query and we will contact you

Brochure

Design Sanctuary

-

Kitchens

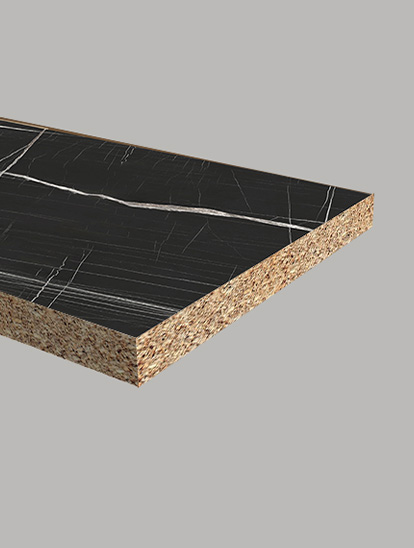

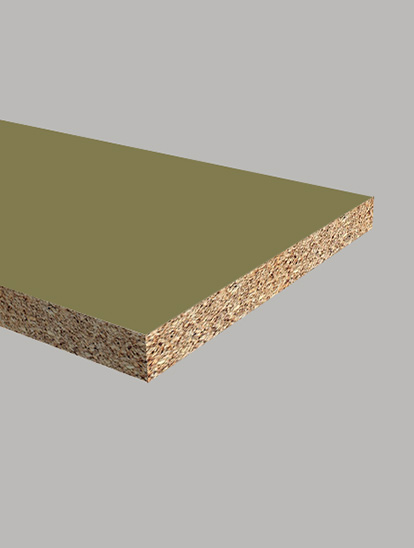

Experience a fusion of beauty and functionality with an innovative chipboard. This revolutionary material withstands everyday wear and tear on cabinets and countertops, while pre-laminated options offer a seamless and stylish finish. Create a kitchen that's both durable and aesthetically pleasing. -

Office Spaces

Embrace a healthier and visually stimulating workspace with an E1-compliant chipboard. Prioritize employee well-being with durable desks, workstations, and furniture that boast a clean and modern aesthetic. -

Retail Chains

Showcase your products with style and functionality. This versatile chipboard allows you to design high-impact shelving, displays, and furniture that perfectly reflect your brand and create a visually captivating shopping experience. Choose from a wide range of pre-laminated finishes for a cohesive look. -

Hotels

Offer guests a comfortable and visually appealing stay with chipboard that combines style and practicality. Moisture resistance ensures lasting durability in high-traffic areas, while strict emission standards guarantee a healthy environment. Create a beautiful and functional space for a memorable guest experience.

Kitchens

Office Spaces

Retail Chains

Hotels

Design Range

Faqs

-

How is FABWOOD a better substrate than MDF and PLY?

FABWOOD delivers high quality and value for furniture industry. FABWOOD is optimized for providing desired quality parameters for specific applications. MDF is recommended for Paint and polish while FABWOOD provides better value for all your needs where strength and superior designs required for your furniture need. Usually, normal Ply are having issues related to High Turn-around-Time, High cost, Defective core & surface. Usually, Ply is processed manually and doesn't deliver similar quality furniture compared to factory (machine) made high end Furnitures.

-

What are the sizes available for Interior Grade Pre-laminated Chipboards?

Below are the standard sizes of Chipboards offered:

Interior Grade Thickness Range : 9,11,15,17,25 mm

Prelaminated Board Size Range : 8' x 4' , 8' x 6' , 9 x 6’ -

What type of wood is used to manufacture FABWOOD?

MERINO FABWOOD Chipboards are made from Pure Eucalyptus tree wood logs which are sustainably sourced through agroforestry.

-

What are the main features of MERINO FABWOOD panels?

Main features are - 1. Ultra-low VOC Emissions 2. Superior load bearing strength 3. Premium design & finishes 4. Most efficient wood utilization 5. Best in class screw holding capability 6. Ultra smooth calibrated surface

-

What are the application areas for FABWOOD Panels?

FABWOOD panels can be used for interior furniture needs in offices, home furniture, retail showrooms, education institutes, hospitality, healthcare, industrial sectors.

-

What are the sizes and thickness available for Raw Chipboards offered by Merino?

Below are the standard sizes of Raw Chipboards offered by Merino:

Raw Board (Size): 8' x 4' , 8' x 6' , 9 x 6’, 10’ x 4’

Raw Board (Thickness) :

Interior Grade: 9,11,15,17,25 mm

Exterior Grade: 9, 12, 16, 18, 25, 30, 32 mm

Note: Special orders with MOQ can be considered for customized sizes up to 20’ x 8’ size. -

Is FABWOOD IS CARB P2 Certified?

applied

-

What are the sizes available for Exterior Grade Pre-laminated Chipboards?

Below are the standard sizes of Chipboards offered:

Exterior Grade Thickness Range : 9, 12, 16, 18, 25, 30, 32 mm

Prelaminated Board Size Range : 8' x 4' , 8' x 6' , 9 x 6’

E-Catalogue

E-Catalogue  Blog

Blog